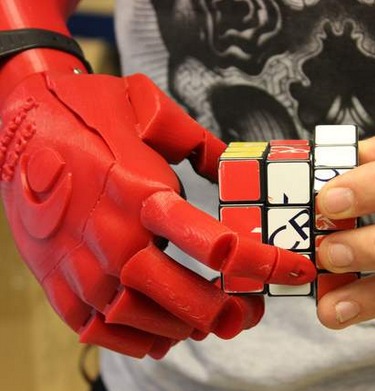

3D-printed robotic hand custom-made in 40 days wins top design award

A 3D-printed robotic hand has been developed that can be custom-made in just 40 days and costs a fraction of other bionic limbs. The technology, developed by Bristol-based engineer Joel Gibbard, has been awarded the 2015 UK James Dyson Award and could now offer amputees a cheaper and quicker alternative. Custom-fitting and production can take weeks but this award-winning design by Open Bionics can take 40 hours to 3D print in a laboratory.

We’ve encountered many challenges in designing our hands but the reactions of the individuals we help fuels our perseverance to bring them to market.

Twenty-five-year-old design engineer Joel Gibbard, who invested £6,000 of his own savings into the project

The company says the low-cost robotic hands can perform the same tasks as expensive, advanced prosthetics, including individual finger movement through the use of electromyographical sensors which are stuck to the amputee’s skin. UK inventor and businessman James Dyson who helped pick the award winner said: “3D printing has been used by engineers as a prototyping tool for decades, but Joel is using it in a new way to provide cheaper, more advanced prosthetics for amputees. It shows how bold ideas don’t need a big budget and if successful his technology will improve lives around the world.”

Technology 3D printing